Folding boxes are ingeniously designed to collapse when not in use, which can reduce storage space requirements by up to 70%. This feature is incredibly beneficial for businesses seeking to optimize warehouse space and implement flexible storage strategies. By minimizing the space occupied by empty containers, companies can maximize their logistics operations, ensuring that every inch of storage space is utilized efficiently. This collapsible design significantly improves storage efficiency, a crucial consideration for businesses dealing with fluctuating inventory levels.

Modern folding boxes are crafted using advanced materials like polypropylene and high-density polyethylene (HDPE). These materials are renowned for their resistance to wear and tear, offering robustness and long-lasting durability. The boxes remain lightweight while ensuring they can be used under various conditions without losing structural integrity. Such characteristics make these folding boxes ideal for repeated use, reducing the need for constant replacements and thus enhancing the sustainability of storage solutions. With these modern materials, folding boxes can provide a reliable and efficient option for long-term use.

The lightweight nature of folding boxes contributes to reduced shipping costs and improved fuel efficiency during transport. Because these boxes require less material and weight, businesses can save up to 30% on logistics costs by using collapsible solutions. The economic benefits are substantial, as reduced weight translates to lower freight charges and fuel consumption. Transitioning to folding boxes not only optimizes cost-efficiency but also enhances the overall environmental sustainability of transportation. This approach is becoming increasingly significant in industries aiming to reduce their carbon footprint and increase operational savings.

Stackable plastic containers are a game-changer for achieving warehouse efficiency. Their ability to allow vertical organization helps maximize warehouse space and accessibility, facilitating better space management. This design not only enables high-density storage configurations but also improves operational efficiencies within the logistics chain. Moreover, utilizing stackable designs in your warehouse can significantly enhance space management by enabling the easy stacking of goods, thus optimizing the use of available vertical space.

Plastic logistics containers offer unparalleled customization options, which can be integral for brand integration. Manufacturers now facilitate custom branding options that allow businesses to display their logos on containers, thereby enhancing product visibility and marketing opportunities. Furthermore, custom designs can be tailored to meet specific functional needs, ensuring the container aligns with product specifications, thus heightening the utility and presentation of the containers in logistics and retail scenarios.

Recent advancements in material science have paved the way for the development of biodegradable and recyclable plastic containers, presenting a sustainable option for environmentally conscious businesses. These eco-friendly materials not only fulfill the requirements of recyclability and biodegradability but also align with broader corporate social responsibility (CSR) initiatives. By embracing these materials, companies can enhance their sustainability profiles and improve their brand reputations in a marketplace increasingly sensitive to environmental impacts.

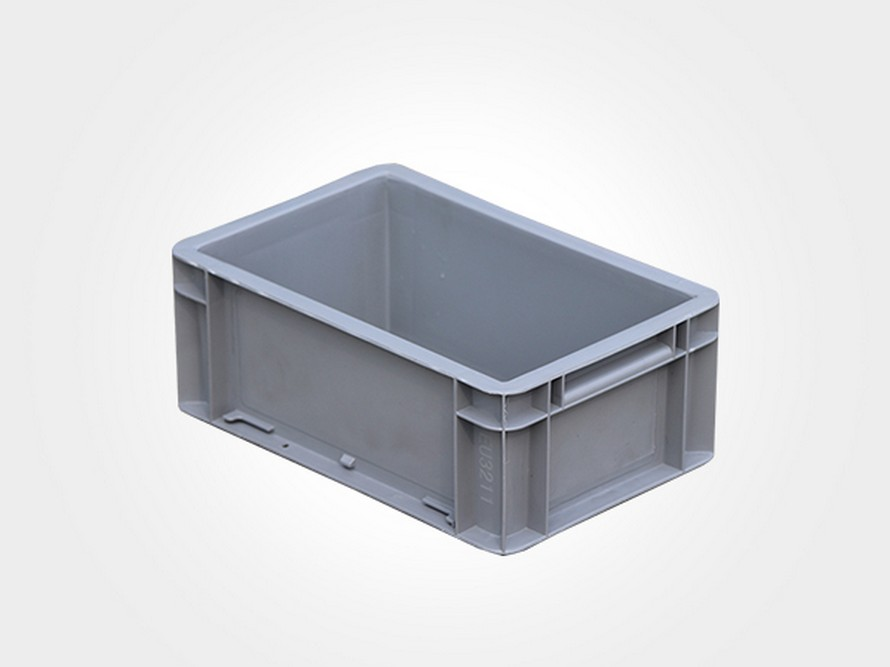

The EU2311 logistics box is an exemplary choice for industrial applications, utilizing high-grade polypropylene to combine durability and lightweight benefits. This box is crafted to ensure exceptional performance across diverse environmental conditions, making it a reliable solution for both shipping and storage needs. Polypropylene's inherent resilience ensures that the box can withstand various handling and transport scenarios. Its compact size makes it particularly useful for industries requiring efficient space utilization without compromising on durability.

Engineered with heavy-duty high-density polyethylene (HDPE), the LK400-120 tote is built to endure significant weight while maintaining its structural integrity. This tote's robust construction makes it an ideal fit for heavy-duty applications in the manufacturing and construction sectors where reliability and durability are critical. The material's impact resistance ensures the tote remains intact under substantial load pressure, making it a preferred choice for tasks requiring heavy-duty storage and transportation solutions.

Designed in accordance with EU regulations, the EU8633 reusable crate offers unparalleled reliability and functionality for logistics operations across Europe. Its compliance with EU standards ensures smooth cross-border transit while also supporting sustainable logistics practices through its reusable design. This crate not only aids in reducing environmental impact but also facilitates cost savings by minimizing waste associated with one-time-use containers, making it beneficial for businesses aiming to enhance efficiency and sustainability in their supply chains.

Known for its durability, the 400-200 HDPE warehouse container is a workhorse for transporting goods within demanding warehouse settings. Its robust build caters to efficient storage and handling, offering ample space to accommodate various types of goods. This container's stackable design streamlines operations by optimizing storage utilization and facilitating smoother workflows, making it indispensable for efficient warehouse management.